For John Dilworth, the humble grain’s oil can enrobe a violin’s bare wood and flaunt its rippling curves

Discover more lutherie articles here

This article is from the June 2013 issue of The Strad

From the tiny linseed the mighty oil does flow. Linseed oil – one of the marvels of the violin maker’s shop. My wife is always happy when I’m varnishing – the house is filled with its aroma, rather than with the usual banging, sawing and swearing. Now I’m not going to get into an argument about whether linseed, poppy or walnut oil was the chosen medium of the masters – I just want to say that linseed oil is one of the most wonderful things there is. It goes with wood like flesh and bone. It dresses the wood, bringing out the figure, intensifying every conceivable advantage of glittering spruce or rippling maple.

For centuries it has been extracted from the humble seed. It dates back to the early 15th century as an artist’s medium, but it must have been used long before that, as a straightforward coating for wood, canvas or whatever. Originally a simple waterproofer, prepared well with stabilising resins it has much greater possibilities – supple, beautiful in colour, it is one of nature’s great gifts to the honest craftsman. Now it can be cold-pressed, hot-pressed, boiled, sun-bleached, anything you like, but to make varnish, we violin makers demand the best. The virgin cold pressing – that is the first oil that oozes from the seed without heat or chemical encouragement. Then the oil has to be washed to get the mucilage out of it – what used to be a long process of filtering through sand or constant washing with water. I don’t bother with that any more. The lovely Swedish oil I can now get is so well prepared that it makes gorgeous (not boasting here) varnish straight from the bottle.

Preparing and using a linseed-oil varnish is quite a painstaking business, compared with the ‘Chinese lacquer’ shellac varnishes that arrived in Europe in the 17th century, and seemed then to make linseed-oil varnish out of date. But they don’t mature like oil does. Oil mixed with resins and coloured with pigments evolves long after its first drying, which takes place by polymerisation – all the molecules of the medium fastening slowly together in a flexible chain. Not simple evaporation, as happens with alcohol varnishes. And the oxidation continues over decades and centuries. The oil becomes more transparent as it saturates the pigments, darkening to that deep golden brown we appreciate so much, and it acquires texture as it shrinks, ebbing and flowing to a microscopic degree over the wood surface.

A while ago, a boat builder asked me in the pub about what I use for varnish. ‘Oil,’ I said. ‘Oh – you mean old-fashioned yacht varnish? Which brand?’ I told him I made it myself and he said, ‘Why?’ I began to describe the entire process. But he’d already wandered back to the bar for another pint.

Read: Cremonese varnish: Shining example

Read: Trade secrets: a method for cooking oil varnish by Nicolas Gilles

Discover more lutherie articles here

This article is from the June 2013 issue of The Strad

An exclusive range of instrument making posters, books, calendars and information products published by and directly for sale from The Strad.

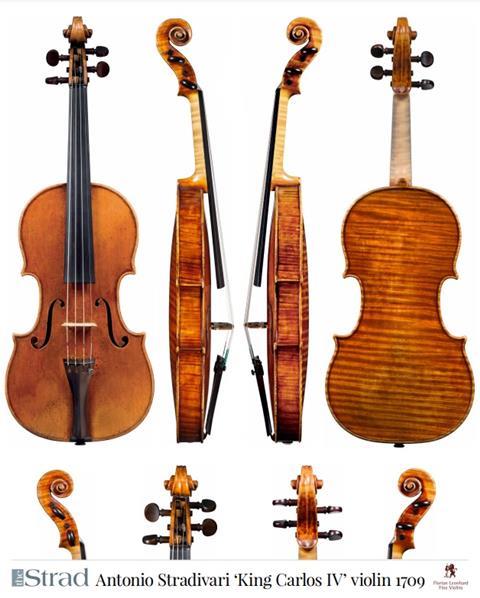

The Strad’s exclusive instrument posters, most with actual-size photos depicting every nuance of the instrument. Our posters are used by luthiers across the world as models for their own instruments, thanks to the detailed outlines and measurements on the back.

The number one source for a range of books covering making and stinged instruments with commentaries from today’s top instrument experts.

This year’s calendar celebrates the top instruments played by members of the Australian Chamber Orchestra, Melbourne Symphony, Australian String Quartet and some of the country’s greatest soloists.

No comments yet