- News

- For Subscribers

- Student Hub

- Playing Hub

- Directory

- Lutherie

- Magazine

- Magazine archive

- Whether you're a player, maker, teacher or enthusiast, you'll find ideas and inspiration from leading artists, teachers and luthiers in our archive which features every issue published since January 2010 - available exclusively to subscribers. View the archive.

- Jobs

- Shop

- Podcast

- Contact us

- Subscribe

- School Subscription

- Competitions

- Reviews

- Debate

- Artists

- Accessories

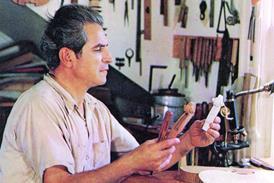

Trade Secrets: Gluing the linings with counterforms and springs

An efficient method for a complex process, which allows freedom of movement

The modelling of the ribs defines the shape of an instrument’s body, and gluing the linings makes the structure perfect. Using an internal mould with counterforms allows for the step-by-step modelling of the violin outline, as well as fine adjustments, from the construction of the mould to the gluing of the linings.

When I start the gluing, I use counterforms that I design and cut at the same time as the internal mould itself. This method gives me pinpoint precision and control. I like to use a stable support, and the firm ribs permit good speed of execution. In addition to the counterforms I use springs as clamps. The ones I’m using now were made by an old artisan who works with steel, but the traditional method at my school was to use mattress springs cut in an open ring. To do this, you need to find an old mattress, extract the coils, and cut them into many rings. The best springs are those made with high carbon steel and a diameter of around 3mm, as they offer good elasticity and mechanical resistance.

I learnt this method from Renato Scrollavezza at the Parma Violin Making School and I still use it today, practically unchanged…

Already subscribed? Please sign in

Subscribe to continue reading…

We’re delighted that you are enjoying our website. For a limited period, you can try an online subscription to The Strad completely free of charge.

* Issues and supplements are available as both print and digital editions. Online subscribers will only receive access to the digital versions.