- News

- For Subscribers

- Student Hub

- Playing Hub

- Podcast

- Lutherie

- Magazine

- Magazine archive

- Whether you're a player, maker, teacher or enthusiast, you'll find ideas and inspiration from leading artists, teachers and luthiers in our archive which features every issue published since January 2010 - available exclusively to subscribers. View the archive.

- Jobs

- Shop

- Directory

- Contact us

- Subscribe

- Competitions

- Reviews

- Debate

- Artists

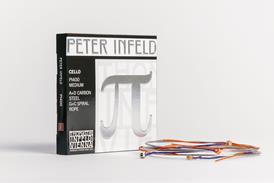

- Accessories

A measured approach

Although the many varied methods of stringed instrument making have been analysed countless times, the actual production process has hardly been questioned in its 450-year history. Luan Amorim and Amanda Schwegler use techniques taken from engineering to survey the time and cost factors – and come up with some unusual ...

‘If you can’t measure it, you can’t manage it,’ wrote the statistician W. Edwards Deming in 1993. Since time immemorial, violin making has been treated as an artisanal pursuit, one that has survived the streamlined production processes of the Industrial Revolution and remains the domain of luthiers at their workbenches. Artisans use their craft as a form of creative expression, eliciting the admiration of those who appreciate it; and their products are generally valued more highly than those created through a mass-production process, with customers seeking both uniqueness and authenticity, as well as often a bespoke instrument catering to their individual needs.

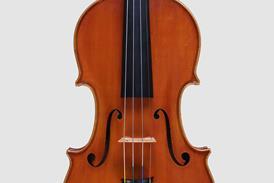

For this and other reasons, there have been very few attempts to examine the production process behind making a stringed instrument using traditional methods; but is it possible that such a investigation, based on those used in industrial engineering, could help us streamline the process and maximise its efficiency? For the study described in this article we tracked the process of making a copy of the 1740 ‘Heifetz’ Guarneri ‘del Gesù’ violin at our workshop in Curitiba, Brazil, investigating the total amount of time and money invested in its creation, and then attempt to draw conclusions on the points that might most easily be modified to make the process more time- and cost-efficient.

To give some idea of our starting point: Amorim Fine Violins Cremona is considered a small family business…

Already subscribed? Please sign in

Subscribe to continue reading…

We’re delighted that you are enjoying our website. For a limited period, you can try an online subscription to The Strad completely free of charge.

* Issues and supplements are available as both print and digital editions. Online subscribers will only receive access to the digital versions.