- News

- For Subscribers

- Student Hub

- Playing Hub

- Directory

- Lutherie

- Magazine

- Magazine archive

- Whether you're a player, maker, teacher or enthusiast, you'll find ideas and inspiration from leading artists, teachers and luthiers in our archive which features every issue published since January 2010 - available exclusively to subscribers. View the archive.

- Jobs

- Shop

- Podcast

- Contact us

- Subscribe

- School Subscription

- Competitions

- Reviews

- Debate

- Artists

- Accessories

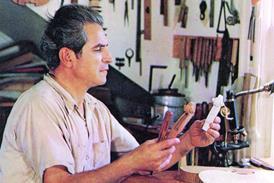

Trade Secrets: Making a single-use mould

A method that can be used when making one-off instrument commissions

A while ago, I was asked to make a three-quarter-sized violin. It was a job I looked forward to but one that I doubted I would ever repeat. The making of a new model requires new templates and forms, as well as a mould (if that is one’s usual mode of manufacture), plus a number of cramping blocks used to exert pressure on the ribs over the blocks as they are glued.

My preference has always been for an inside mould, and I formerly used ones similar in construction to those of the Stradivari forms. Their manufacture, and the associated blocks, are quite time-consuming but they can be used over and over again. For this single use, I decided to make a different kind of mould which would be quick and easy to construct. It would also be accurate, both in outline and in the heights of the ribs, so that they would be the same as their finished height on the instrument. Then they would require no cramping blocks to secure the ribs as they were glued on to the mould.

The finished mould was so successful that I now use this type for all the instruments I make, including experimental models. Last year I made another ‘one-off’: a seven-eighths violin. This year I will be making an experimental 40cm viola, and below is the process I utilised to make and use the mould…

Already subscribed? Please sign in

Subscribe to continue reading…

We’re delighted that you are enjoying our website. For a limited period, you can try an online subscription to The Strad completely free of charge.

* Issues and supplements are available as both print and digital editions. Online subscribers will only receive access to the digital versions.